About High Temperature CO2 heat pumps

Why use CO2 heat pumps to make buildings more sustainable?

The current world market for heat pumps is growing rapidly. Virtually all of them use R407C, R410A or R134A, which are very powerful greenhouse gases with relativily high global warming potentionals (GWP). Although the refrigerant leakages from these systems are small, they cannot be neglected. An alternative solution is to utilize refrigerants that don’t have a negative impact on the global environment. For example non-synthetic fluids such as ammonia, hydrocarbons and carbon dioxide. Carbon dioxide (CO2, R744) is one of the few non-toxic and non-flammable fluids that contributes neither to ozone deplation or global warming. Due to its favourable thermophysical properties, R744 is regarded as an interesting alternative instead of the HFC’s in residential and commercial heat pumps.

A CO2 heat pump functions in the same way as a heat pump with conventional refrigerants. By using CO2 as a refrigerant, the heat pump can operate much more efficiently in a high temperature range and performs more efficiently at low ambient temperatures. Due to the maximum outlet temperature of 90°C, the CO2 heat pumps can be used for the production of domestic hot water.

When the heating installation combined with the buffer tanks is adjusted correctly, the CO2 heat pumps can used to completely replace existing gas boilers for space heating. Existing central heating installations often require a minimum supply temperature of 80°C. The CO2 heat pumps are therefore an excellent device to make existing buildings more sustainable. The CO2 heat pumps are suitable for collective heating in apartment buildings, small district heating systems, sanitary hot water production for swimming pools, sports accommodations, hotels and holiday parks.

How do CO2 heat pumps function most efficiently?

Residential CO2 heat pump systems for space heating and hot water heating achieve the same or better seasonal performance factor (SPF) than the most energy efficient state-of-the-art heat pumps as long as:

- The CO2 heat pump unit covers the entire DHW heating demand and the annual heat delivered for DHW production is minimum 25 to 30% of the total annual heat delivered from the heat pump.

- The CO2 heat pump unit is operated in the combined heating mode when there is a simultaneous space heating and DHW heating demand.

- The return temperature in the space heating system is about 30°C or lower.

- The city water temperature is about 15°C or lower

Coefficient of Performance (COP) of a CO2 Heat Pump

The thermal losses due to the good insulation of the storage tanks are low. Maximum conductive heat transfer between the hot system water and cold water during tapping and charging is recommended. In contrary to conventional heat pump systems for combined space heating and DHW heating, the CO2 heat pump system achieves the highest COP in the combined heating mode and the DHW heating mode. The lowest COP in the space heating mode. Hence, the larger the annual DHW heating demand, the higher the SPF of the combined CO2 heat pump system.

The lower the return temperature in the space heating system and the lower the DHW storage temperature, the higher the COP of the CO2 heat pump. A low return temperature in the space heating system also results in a moderate domestic hot water heating capacity ratio, which means that a relatively large part of the annual space heating demand can be covered by operation in the combined heating mode, where the COP is considerably higher than in the space heating mode only.

During operation in the combined heating mode and the domestic hot water heating mode, the COP of the CO2 heat pump is heavily influenced by the outlet system water temperature after the city water preheating heat exchanger. The lower the inlet temperature to the gas cooler, the higher the COP.

Compressor of the CO2 heat pump

The COP for CO2 heat pumps is generally more sensitive to variations in the compressor efficiency than that of conventional A/W and W/W heat pump systems. It is therefore of particular importance to apply a high-efficiency compressor. After in-house independent research the engineers developed a high-efficiency compressor.

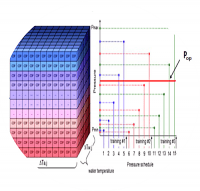

Pressure Control of the CO2 heat pump

The CO2 heat pump system will be more complex than the state-of-the art residential heat pump systems due to the requirement for a high efficiency gas cooler, extra valves and tubing for by-pass of fluids, an inverter controlled pump in the system water circuit as well as an especially designed storage tank. The application of optimum high-side pressure control will further increase the efficiency of the CO2 heat pump systemt.

Gas Cooler Design of the CO2 heat pump

Evaluation due to the low critical temperatures of CO2, a CO2 heat pump unit will give off heat by cooling of CO2 at supercritical pressure in a gas cooler. In order to achieve a high COP, it’s essential that useful heat is given off over a large temperature range, resulting in a relatively low CO2 outlet temperature from the gas cooler. Important is the production of system water in the required temperature range from 60 to 85°C. To contribute the highest possible COP for the CO2 heat pump unit a number of gas cooler configurations were evaluated. The final design of the gas cooler resulted in an increase of the heat transfer of 30%.

Special storage tank for a CO2 heat pump

Conductive heat transfer between the system water and the cold city water in the storage tank during the tapping and charging periods may result in a considerable decrease in the inlet water temperature for the gas cooler. These large temperature differences for the system water and the city water, combined with small controlled charging flows increase the gas cooler heating capacities. This will in return increase the COP of the CO2 heat pump.

One possible way to improve internal conductive heat transfer is to separate the system water and the city water by means of a heat exchanger. This concept proved to give satisfactory thermal performance improvement and a better functionality of the whole heating system. Further functionality and thermal performance can be optimized by a special storage tank. In this storage tank system water and DHW are separated. A heat exchanger between incoming city water and system water can lower the return temperature to the gas cooler.

Research and development of the CO2 Heat Pump

2009 - 2011

Engineer and inventor, Dr. Qi Pengcheng, set up a special team in Xi’an Jiaotong University to start the research and development of a transcritical CO2 compressor. In 2011 the research and development of CO2 heat pump systems started.

2012 - 2013

The transcritical CO2 compressor has been successfully developed and passed the 500 hour life time test. In 2013 The first 70 kW CO2 heat pump system was successfully developed and passed the test of Hefei General Machinery.

2014 - 2015

In 2014 one completed the construction of a large scale CO2 heat pump system test laboratory. Together with Hengda Technology the first CO2 heat pump demonstration project was developed. The CO2 heat pump project for Xinjiang Railway Station passed the acceptance successfully.

2016 - 2017

Hengda Technology began to widely apply CO2 heat pumps in high-end hot water and heating projects in domestic and foreign markets. In 2017 the first large scale cascade CO2 heat pump system has been successfully developed and installed.

2018 - 2019

Dr. Qi Pengcheng won the first prize of Science and Technology of Shaanxi Province based on the development of CO2 compressor with heat pump. Based on the breakthrough of key technologies of CO2 heat pumps Dr. Qi Pengcheng won the second prize of national Science and Technology Progress award.